The 2025 China International Fair for Trade in Services (CIFTIS) opened this week at Beijing's Shougang Park, with green and smart technologies in focus. CSCEC featured in the engineering consulting and construction services section, presenting its Quality Housing solutions, sustainable building materials, intelligent robots, green technologies, smart equipment, smart site management, and integrated digital systems, underscoring its advances in sustainable and high-quality construction.

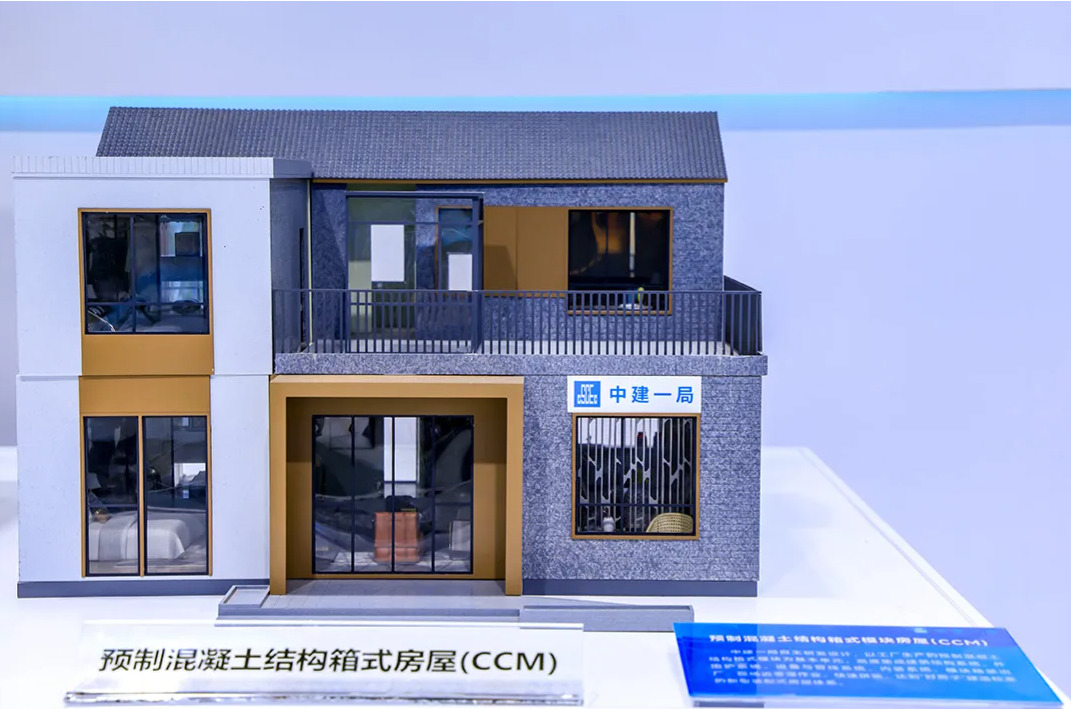

Its Quality Housing initiative covers three models—new urban homes, rural housing, and urban renewal—designed to deliver safe, comfortable, energy-efficient and smart living. Smart technologies cut energy use in new housing projects, while prefabricated concrete modular units enable fast, high-quality builds in rural and renovated homes, with residents able to customize designs.

Among the highlights were next-generation equipment and materials: the company's second-generation skyscraper-building machine, which integrates efficiency, safety, and sustainability. It enables reduced manpower or even fully unmanned operations in core procedures and on-site safety management.

The second-generation skyscraper-building machine integrates efficiency, safety, and eco-friendly performance, enabling reduced manpower or even fully unmanned operations in related processes and on-site safety management.

Second-generation skyscraper-building machine

Modular bathrooms allow the core structural components of restrooms to be assembled quickly on-site like building blocks. At Hanyun Mansion in Wuhan, a wide range of CSCEC's self-developed smart construction achievements have been applied.

Modular bathrooms

The unmanned material transport system, designed for secondary structure and finishing stages, supports various modes of material handling. It enables autonomous pickup, cross-floor transport, remote scheduling, and precise supervision.

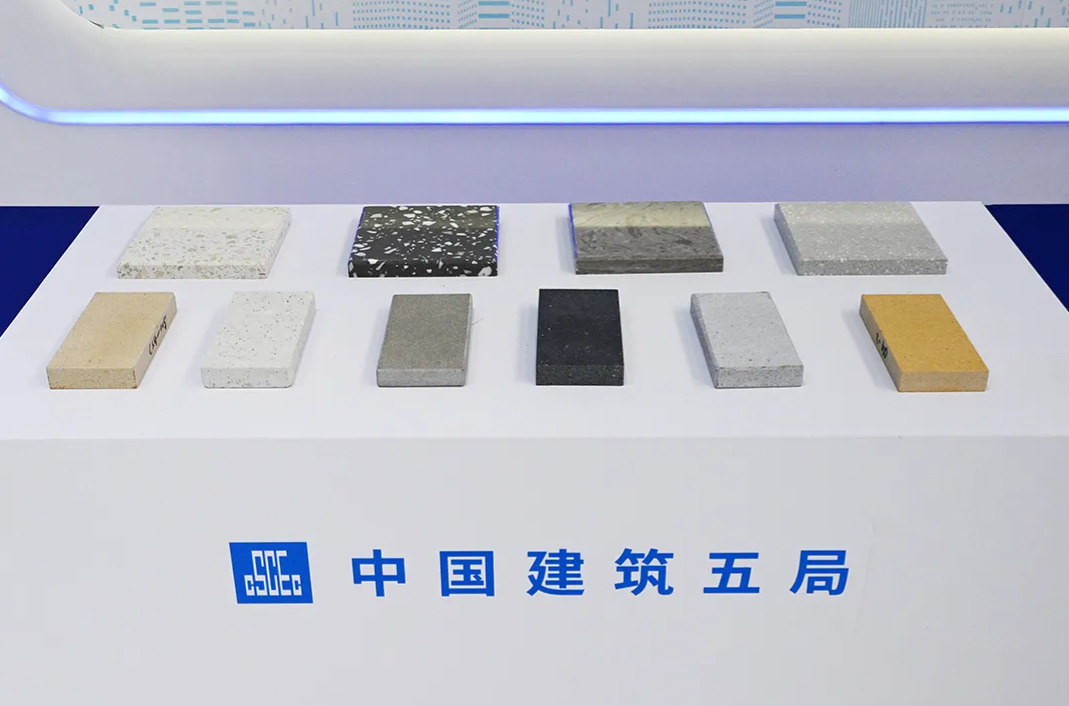

New eco-friendly stone, produced from demolition waste and metallurgical solid waste, requires no firing and outperforms natural stone and ceramic tiles in hardness and stain resistance. Its production process reduces carbon emissions by more than 60% compared with traditional artificial stone panels.

New eco-friendly stone

The stone-making machine, an on-site recycling line for metro shield tunnel muck, transforms high-moisture spoil into a variety of eco-friendly building products, helping reduce costs and carbon emissions.

The Longyan Bridge, the world's first cable-stayed bridge that uses horizontal double rotations technology, has set nine world records.

Exhibition visitors viewing the Longyan Bridge model

Prefabricated rail transit products have been successfully applied in more than 20 major projects, including Beijing Metro Lines 8, 11, and 17. These solutions reduce manpower requirements by 80%, cut carbon emissions by 60%, and improve construction efficiency threefold.

The graphene adiabat noncombustible board is hailed as the “all-round warrior” of the insulation industry, offering excellent thermal performance, low water absorption, high stability, and convenient installation. CSCEC has established an automated production line with an annual capacity exceeding one million square meters, already applied in projects in Shandong, Beijing, and beyond.

The autoclaved lightweight concrete (ALC) panel construction robot, designed for automated installation of ALC panels, realizes fully intelligent operation, mainly used for interior and exterior wall installation in public buildings and factories.

ALC panel construction robot

In the field of new-type building industrialization and intelligent construction, the Hualong One advanced construction technology was unveiled as a complete package for the first time, addressing numerous technical challenges in third-generation nuclear power projects. Key technologies in metal roofing construction and large-scale cultural and tourism project construction also drew significant attention.