Modular, Zero-Energy Consumption Building

Located in the Pudong New Area of Shanghai, China, the zero-carbon building exhibition center developed, designed, and constructed by CSCEC is the first modular and zero-energy consumption building in China. This nearly 4,000-square-meter building is equipped with photovoltaic panels, photovoltaic curtain walls, and the best insulation materials, and was built using a "building blocks" approach.

The builders of CSCEC installed photovoltaic panels on the roof and photovoltaic curtain walls on the west façade of the building, effectively turning the building into a "power plant" that generates 124,000 kilowatt hours of electricity per year, reducing carbon emissions by 52 tons, and using renewable energy to replace the original power input, achieving zero energy consumption.

The exhibition center adopted a modular construction method, with the modular boxes produced in the factory and transported to the site for assembly, and without formwork or welding. The method resulted in a 50% reduction in construction time and an 80% reduction in on-site waste. In the future, modular boxes can be reused, with a safe service life of more than 50 years.

By comparing different materials, the builders laid a layer of insulation material on the exterior walls of the building, which is four times thicker than that of a typical building, achieving both heat insulation in summer and warmth preservation in winter, thereby accelerating zero energy consumption.

MiC Modular Building

The total construction area of the Baguang Ecology International Hotel in Shenzhen, built by CSCEC, is 253,000 square meters, and it uses the advanced intelligent construction technology, MiC (Modular Integrated Construction), to divide the building into three-dimensional units. Each unit's process is completed in the factory at once, and only needs to be assembled at the site. Compared with traditional construction methods, it can reduce about 70% of construction waste, 50% of construction carbon emissions, and 25% of material waste.

Curtain Wall Technology:

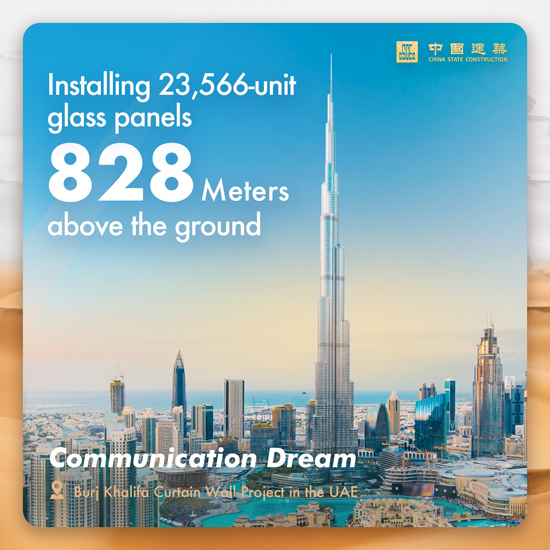

Burj Khalifa Project in Dubai

The curtain wall project of Burj Khalifa in Dubai, constructed by CSCEC, consists of 23,566 plates. The project is 162 floors and 828 meters high, with the vertical 2~54°C climate temperature difference and challenging 55m/s rare wind force during construction. The CSCEC team successfully created large three-dimensional adjustable curtain wall connectors, set up separation and edge sealing to reduce pressure differences inside and outside the rain screen, and solved many design and construction problems caused by high wind pressure and large structural displacement.

Circular Elevators:

CSCEC has developed a single-tower, multi-shaft circulating construction elevator, which hangs multiple cages on a single guiding track and sets up a rotating mechanism. It only takes 40 seconds for the cage to turn to the other side, achieving a 180-degree rotation of the cage in the air, which is very suitable for construction above 150 meters.

The CSCEC builders have developed a multi-verification flat positioning device to ensure the accuracy of the height of the elevator. They have also adopted a redundant design with two separately powered lines, as well as rotation immobility and rotation exclusivity design to ensure the safety of operation.